The Ultimate Guide To OQ in pharmaceuticals

If cut-off dates are specified in the learn manufacturing instruction (see 6.forty), these time limits needs to be achieved to ensure the caliber of intermediates and APIs. Deviations ought to be documented and evaluated.

Methods really should present for evaluating the impurity profile of each reworked batch against batches created from the founded course of action. Where schedule analytical strategies are inadequate to characterize the reworked batch, more approaches need to be made use of.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Another method could possibly be made use of if such technique satisfies the necessities from the relevant statutes and polices.

Every batch of secondary reference conventional needs to be periodically requalified in accordance using a composed protocol.

Batch output and laboratory Manage information of critical process ways really should be reviewed and accepted by the standard unit(s) before an API batch is introduced or distributed.

There have not been important system/products failures attributable to triggers besides operator error or gear failures unrelated to gear suitability

Products cleaning/sanitation scientific studies ought to deal with microbiological and endotoxin contamination for all those procedures wherever There exists a have to have to lessen overall microbiological depend or endotoxins in the API, or other procedures where by this kind of contamination might be of issue (e.g., non-sterile APIs accustomed to manufacture sterile products and solutions).

Any resampling and/or retesting after OOS results must be carried out according to a documented course of action.

All get more info files relevant to the manufacture of intermediates or APIs must be ready, reviewed, accepted, and dispersed In line with prepared treatments. These files is often in paper or Digital variety.

This assistance represents the Food and Drug Administration's (FDA's) existing considering on this matter. It does not generate or confer any legal rights for or on any person and does not function to bind FDA or the public.

Thereafter, at least 1 batch every year of API produced (Except none is produced that calendar year) need to be extra to The soundness checking software and tested at the very least every year to substantiate The steadiness.

Intermediates might or might not be isolated. (Notice: this steerage only addresses those intermediates created following the stage that a firm has defined as The purpose at which the creation of the API begins.)

Correct controls more info should be established in any respect phases of manufacturing to make certain intermediate and/or API excellent. While this direction begins with the cell culture/fermentation step, prior techniques (e.

Jaleel White Then & Now!

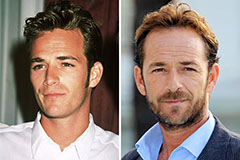

Jaleel White Then & Now! Luke Perry Then & Now!

Luke Perry Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now!